High quality surfaces with outstanding precision and beauty

Aluminium makes it possible to produce attractive high-end parts. Its material properties, weight and metallic feel are indeed reason to take advantage of aluminium’s special mechanical and decorative characteristics.

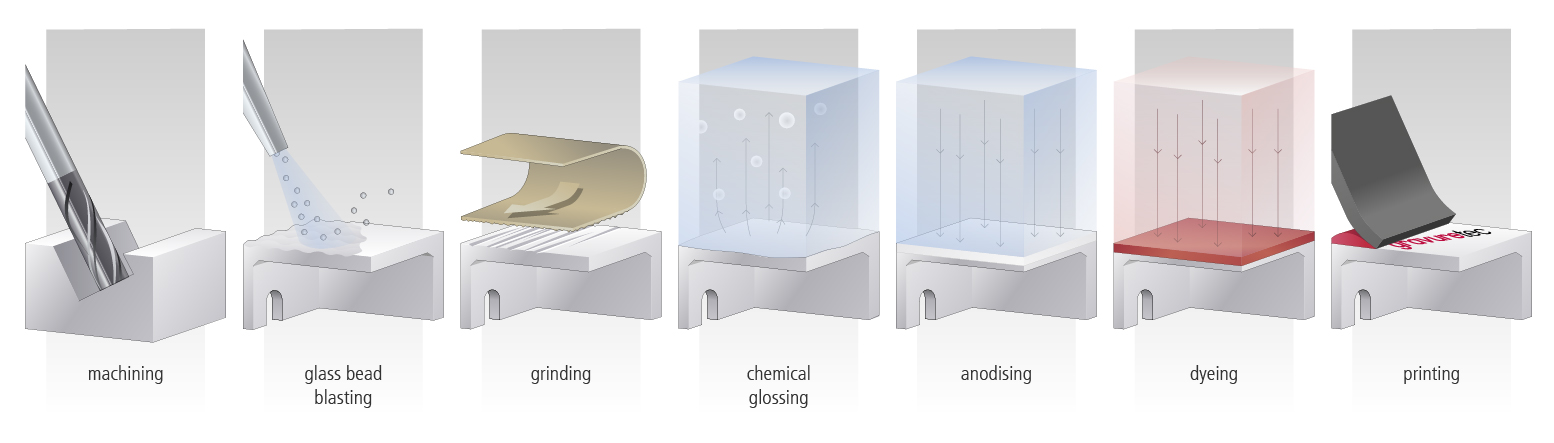

The production of aluminium parts involves a series of processes, all of which have been developed by gravuretec. Equipment, baths and machinery are all on-site. Expert staff with many years of experience and an eye for detail make this possible.

Everything under one roof: short cycle times with monitored interfaces

Large parts milled from the solid material. End-to-end processing. Freeforms. Four systems, two of which are 5-axis processing centres. Maximum dimensions for end-to-end processing: 450 x 450 x 150 mm. Pallet changer for unmanned cycle times.

Matt surfaces that are like velvet to the touch. Bead sizes ranging from 90-150 μm to 400-600 μm.

Character and style achieved by a selective grinding pattern.

Chemical glossing

For that very special look. A chemical abrasion bath process gives aluminium that very special decorative shine.

The transparent, extremely hard oxide layer protects the aluminium and seals in pigments. Fully automated anodising line.

Immersion bath dying process. The pigments are sealed into the oxide layer and do not wear off. Wide selection of colours.

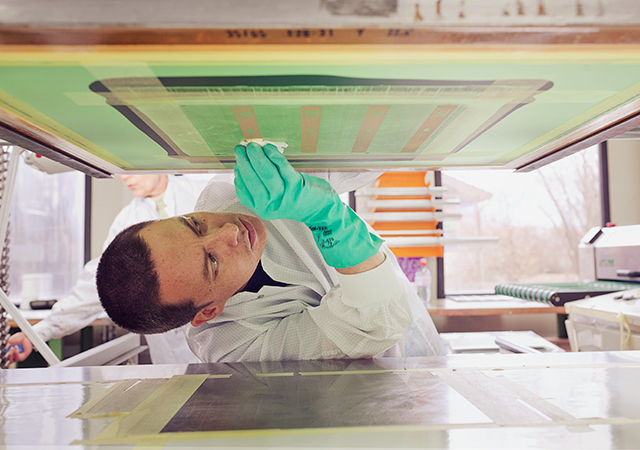

Sub-eloxal process for screen or digital printing. Prints with different colours and paints. Highly experienced team. Cleanroom.

gravuretec has been working with aluminium for over 80 years.

The creation of decorative surfaces requires experience and knowledge of the processes, quality equipment and staff capable of meeting the challenge of producing impeccable parts. gravuretec – precision works has been working with aluminium for over 80 years.

The company’s evolution into a finishing centre for aluminium parts with control of the entire process chain is the outcome of decades of experience. gravuretec sa is synonymous with technical expertise, high flexibility, even for small batches – and unparalleled quality. The company offers surface technology for casing, input systems and industrial signs.