ALUMINIUM FRONT PANELS

Our sub-anodised printing utilizes a process in which inkjet graphics and text are introduced at a level beneath the glass-hard outer surface, a surface which serves to protect the panel and the printing from mechanical and chemical degradation, even in harsh environments. The input system for your device or machine is, therefore, protected over the years from damage.

However painted and printed front panels are perfect as device fronts for environments where high solvent and chemical resistance or high corrosion and abrasion resistance is expected.

Profile front panel

| Application areas: | front panel / broadband transmission technology |

| Surface: | bright rolled and milled finish, rear side chromated |

| Material: | Aluminum alloy Almg3 / 10 mm |

| Lettering/Printing: | 1-colour subsurface digital printing |

Profile front panel

| Application areas: | front panel / broadband transmission technology |

| Surface: | bright rolled and milled finish, rear side chromated |

| Material: | Aluminum alloy Almg3 / 10 mm |

| Lettering/Printing: | 1-colour subsurface digital printing |

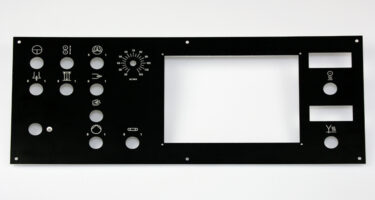

Painted and printed front panels

| Application areas: | electrical engineering |

| Surface: | painted, rear side chromated |

| Material: | aluminum alloy Almg3 / 1.5 mm |

| Lettering/Printing: | 2-colour 2K print |

Painted and printed front panels

| Application areas: | electrical engineering |

| Surface: | painted, rear side chromated |

| Material: | aluminum alloy Almg3 / 1.5 mm |

| Lettering/Printing: | 2-colour 2K print |

Labelled front plate out of anodised aluminium

| Application areas: | device, gadget-/ machine construction |

| Material: | anodised aluminium / 2 mm |

| Lettering/Printing: | sub-anodised printing |

Labelled front plate out of anodised aluminium

| Application areas: | device, gadget-/ machine construction |

| Material: | anodised aluminium / 2 mm |

| Lettering/Printing: | sub-anodised printing |

Fulfilled requirements

- industrial-suited

- high design requirements

- colour fastness

- long term inscription

Mixing console

| Application areas: | audio, mixing consoles |

| Material: | anodised aluminium / 2.5 mm, printed and processed |

| Lettering/Printing: | Sub-anodised printing |

Mixing console

| Application areas: | audio, mixing consoles |

| Material: | anodised aluminium / 2.5 mm, printed and processed |

| Lettering/Printing: | Sub-anodised printing |

Fulfilled requirements

- non-wearing

- precision in printing and mechanical treatment

- long term inscription

Anodised frontpanel

| Application areas: | device, gadget-/ machine construction |

| Surface: | bright rolled and milled finish, rear side chromated |

| Material: | aluminium alloy Almg3 / 1 mm |

| Lettering/Printing: | 1-colour subsurface digital printing |

Anodised frontpanel

| Application areas: | device, gadget-/ machine construction |

| Surface: | bright rolled and milled finish, rear side chromated |

| Material: | aluminium alloy Almg3 / 1 mm |

| Lettering/Printing: | 1-colour subsurface digital printing |

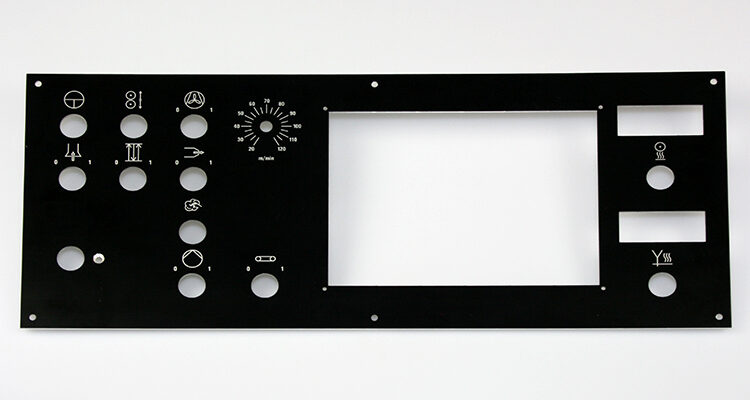

Punched front panel

| Application areas: | mechanical engineering |

| Surface: | bright rolled and milled finish |

| Material: | aluminium alloy Almg3 / 1.5 mm |

| Lettering/Printing: | 4-colour subsurface digital printing |

Punched front panel

| Application areas: | mechanical engineering |

| Surface: | bright rolled and milled finish |

| Material: | aluminium alloy Almg3 / 1.5 mm |

| Lettering/Printing: | 4-colour subsurface digital printing |