PORTAL MILLING MACHINE

highly productive, unmanned production

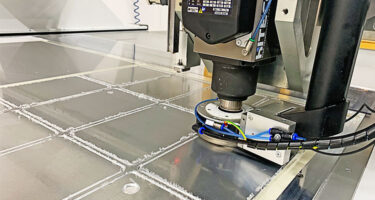

gravuretec recently commissioned a portal milling machine for the processing of aluminium and plastic.

The vacuum clamping surfaces and vilmill™ milling underlay guarantee the reliable fixing of delicate parts made from aluminium or plastic. By using the swarf suction bell, the machine prevents scratches and no cleaning is required.

The new system features the following performance characteristics:

Large working surface for long cycle times

Economical use of the vacuum clamping surfaces, energy efficient

No surface scratching, no cleaning required

Measurement of visual and mechanical features and characteristics within the process

High feed speeds with excellent edge quality

Secure fixing enables reliable processing and automated operation

3-axis milling machine for maximum productivity and continuous running

Unmanned processing and short set-up times