DYNAPIC®

Piezo technology for input systems – strong, robust and resistant

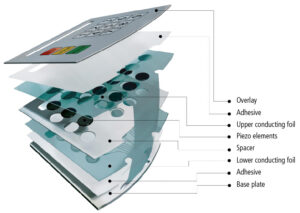

The pressure-sensitive touch technology DYNAPIC® features a ceramic piezo element behind each key. These provide contact with printed conductor films. The entire input system also includes an operating panel (overlay) and a support plate.

There is a wide choice of overlay materials as the switching cycle is triggered by the distortion of the piezo element by just a few micrometers: aluminium, stainless steel, glass or plastic are the most common, allowing the development of extravagant design ideas.

Robust construction

DYNAPIC® consists of different laminated layers. In the key area there are ceramic elements called piezopills. The power generates a charge in the piezopills which is used as a switch signal. The top membrane only goes through a small, elastic deformation. That’s why DYNAPIC® keyboards are extremely robust and resistant.

Application in rough environment

Resistance to vandalism, guaranteed precise switching and a high degree of user-friendliness are amongst the most important features of this unique flat keyboard.

Intensive use

The pathless application allows a simple and solid construction with a small depth of installation.

Advantages

- Vandal resistant

- Suppression of electromagnetic interference

- Much more robust than membrane keyboards

- Insensitive against mechanical wear

- Unaffected by changes in air pressure

- Various overlay materials available

- Adjustable operating force

Typical applications

- Washing machines

- Dish washers

- Coffee machines

- Chemistry and laboratory instruments

- Cash machines

- Vending machines

- Cashless payment systems

- Weighing and pay stations

- Railway

- And many more

Technical data

up to 200 N/cm2

from 0.1 to 100 N

approx. 10 N/s

> 1000 Hz

–40°C to +85°C

–40°C to +85°C

> 10 millions

1V/N (burden 10MOhm)

70 ms (burden 10MOhm)

0.2–1.0 mm, norm 0.8 mm

0.5–1.0 mm, norm 0.5 mm

0.3–0.5 mm

0.5–0.8 mm

The choice of material strength can be influenced by the spacing between the keys.